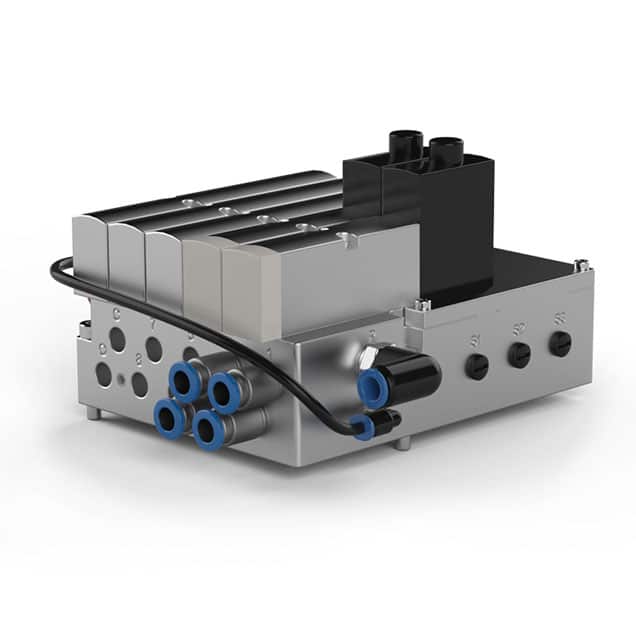

Robotic Systems Products’ valve units are manufactured for simply mounting Air and electrical connections, they are combined into one compact unit which mounts directly to the side of the robot on robust mounting plates, the valve units control the end of arm tooling. When using our valve units together with our tool changers, the air supply will simply shut off automatically during tool changes. Sensor interfaces, field buses, and vacuum modules are available as optional extras.

- Plug & Play modules

- Reduced installation time

- Designed for robot mount

- Standard (ISO) valve interface

- Integrated electrical connection box

- Optional tool changing function

- Optional fieldbus interface

- Optional vacuum module

What Are Robotic Valve Units and How are they Used?

Robotic Valve Units are one of the key instruments in making a warehouse function as efficiently as possible. In combination with tool changers, Robotic Valve Units allow customers to maximize the value each warehouse robot provides to their company. To fully understand Robotic Valve Units the individual must consider three primary topics.

First, the general concepts involved in warehouse robotics should be contemplated. Secondly, one should think about what Robotic Valve Units are and how they work. Finally, the potential benefits of implementing these products should be evaluated.

Core Goal of Warehouse Robotics

Warehouse robotics refer to a broad category of optimizations using software and machinery to maximize efficiency by increasing safety, speed, and repeatability of tasks. Warehouse robots are able to accomplish many tasks which could be dangerous for human workers due to the heavy weights involved, use of cutting tools, height of workspaces, or perhaps the chemicals being used in the processes.

Using robots to perform these kinds of jobs is an important part of keeping the warehouse safe for employees. Well-designed machines can also execute jobs with far greater speed and precision than human employees, which increases profitability for the company.

In today’s global marketplace every company needs to continually evaluate methods for cutting costs so that their products can remain competitive. Robots particularly excel in performing reiterative tasks which require the same motion to be completed hundreds or even thousands of times each day.

These sorts of tasks are typically not satisfying work for employees since they do not allow the worker to use their problem-solving abilities or their creative thinking. Thus, warehouse robotics has the overall goal of streamlining the warehouse by having robots perform the simplest, most repetitive labour.

How Robotic Valve Units Work

As mentioned, Robotic Valve Units are a key piece in accomplishing the overall goal of warehouse robotics. In their simplest form, each warehouse robot is only capable of performing a single task, albeit the robot will perform that task with speed and precision ad infinitum.

Robotic Valve Units however, permit a single robot to perform multiple tasks, further streamlining the warehouse operation. The Robotic Valve Units allow for the simple mounting of multiple air and electrical connections at the end of the robotic arm. The robot will then be able to modify the power and pressure it uses as needed for whatever tasks it is programmed to do.

If the optional tool changing function is installed as well, then the capabilities of the robot will expand even further. The Robotic Valve Units are intelligently designed so that the air supply will automatically be disconnected while the robot is changing tools, and seamlessly depressurizes once the switch is completed.

Benefits of Implementation

Robotic Valve Units represent a superb value proposition. Just as it is more efficient to use warehouse robots, for repetitive tasks, rather than human workers, it is likewise more efficient to use a single robot instead of two or three robots.

Warehouse robots equipped with Robotic Valve Units are more efficient than their counterparts. In turn this reduces overhead for power usage, parts supply, and technician servicing. The ability to maximize the value from a single robot also reduces the footprint that is taken up on the factory floor. This in turn can either promote increased safety of movement, or be used to install other value-producing equipment. This sort of increased efficiency is perfectly in harmony with the overall goal of deploying warehouse robotics in general.

Conclusion

Robot System Products understands the challenges facing businesses in today’s global marketplace. This is why the Robotic Valve Unit has been developed with attention both to its capacity to offer flexible engineering solutions, and on its proven ability to reliably work for millions of duty cycles.

As part of the Billington Safety Systems family, Robot System Products is committed to delivering straightforward products that are field-proven. The Robotic Valve Unit has been designed to be user-friendly as a Plug & Play module with a standard (ISO) valve interface. Optional upgrades such as sensors, a vacuum module, or fieldbus interface allow the Robot Valve Unit to be customized to your specifications.

These various configurations give you the potential to have your robotic workforce evolve with additional capabilities as your needs become more complex. If you have more questions about how Robotic Valve Units can assist your company, feel free to contact us today.

Related Products: Robot Tool Changers | Swivel Tool Changers | Swivels | CIRO | Hose Packages | Tool Systems | Robot Grippers